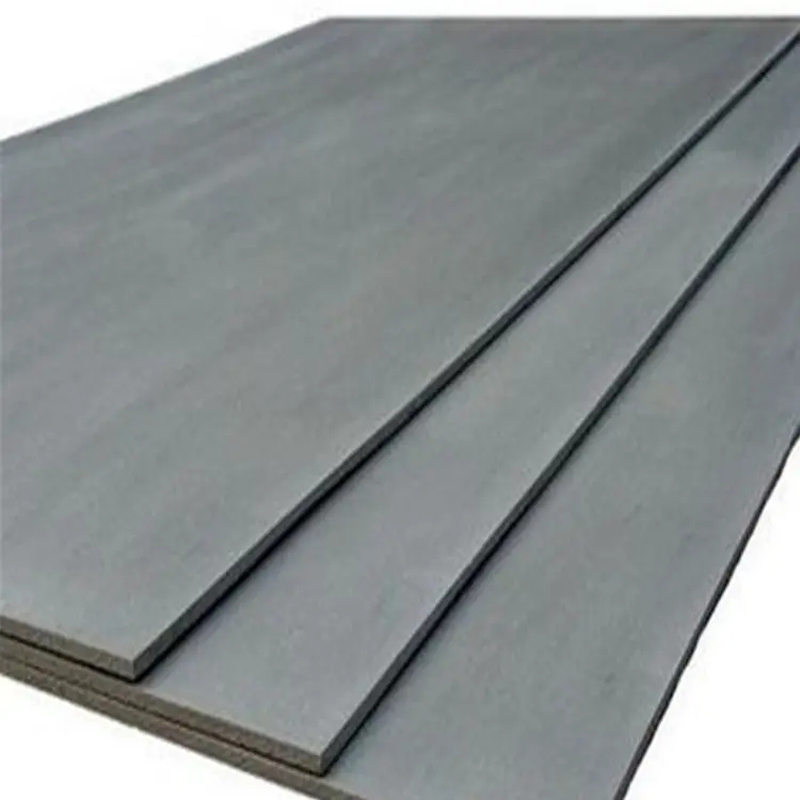

Chithunzi cha SA588 SA387 Aloy Steel Plate

Chikoka cha zinthu aloyi pa ndondomeko katundu zitsulo

1. Mphamvu ya zinthu za alloy pakuchita zitsulo zoponyera

Kutsika kwa kutentha kwa mizere yolimba ndi yamadzimadzi ndikuchepetsera kutentha kwa crystallization, ndi bwino kuponya ntchito.Chikoka cha zinthu za aloyi pamachitidwe oponya zimatengera makamaka kukopa kwawo pazithunzi za gawo la Fe-Fe3C.Kuphatikiza apo, zinthu zambiri, monga Cr, Mo, V, Ti, Al, zimapanga carbide kapena tinthu tating'ono ta oxide muzitsulo, zomwe zimawonjezera kukhuthala kwachitsulo, zimachepetsa kutulutsa, ndikuwononga ntchito yoponya.

2. Chikoka cha zinthu aloyi pa Machining pulasitiki zitsulo

Pulasitiki processing lagawidwa kutentha processing ndi kuzizira processing.Zinthu za alloy mu njira yolimba, kapena mapangidwe a carbide (monga Cr, Mo, W, etc.), amathandizira kukana kwazitsulo zachitsulo komanso kuchepa kwakukulu kwa thermoplasticity komanso kosavuta kupanga ndi kusweka.The matenthedwe processing ndondomeko ntchito wa ambiri aloyi zitsulo ndi zoipa kwambiri kuposa carbon zitsulo.

3. Mphamvu ya aloyi zinthu pa kuwotcherera katundu zitsulo

Aloyi zinthu zonse kumapangitsa quenability chitsulo, kulimbikitsa mapangidwe Chimaona minofu (martensite), ndi kupanga kuwotcherera ntchito zoipa.Komabe, chitsulocho chili ndi Ti ndi V pang'ono, zomwe zimatha kupititsa patsogolo ntchito yowotcherera yachitsulo.

4. Chikoka cha zinthu aloyi pa zitsulo kudula ntchito kudula ntchito zimagwirizana kwambiri ndi kuuma zitsulo, zitsulo ndi oyenera kudula processing kuuma osiyanasiyana 170 HB ~ 230 HB.Kudulira kwachitsulo cha alloy wamba kumakhala koyipa kuposa chitsulo cha kaboni.Komabe, kuwonjezera koyenera kwa S, P, Pb ndi zinthu zina kungathandize kwambiri kudula zitsulo.

5. Chikoka cha zinthu aloyi pa ntchito ya kutentha kutentha ndondomeko zitsulo

Kuchita kwa njira yopangira kutentha kumasonyeza kuvutika kwa chithandizo cha kutentha kwachitsulo ndi chizolowezi cha kutentha kwa kutentha.Zimaphatikizapo quenability, kutenthedwa kwa kutentha, kutentha kwa mpweya ndi oxidative decarbonization.Chitsulo cha aloyi chimakhala ndi quenability yayikulu, ndipo njira yoziziritsa pang'onopang'ono ingagwiritsidwe ntchito pozimitsa, zomwe zimatha kuchepetsa kupindika ndi kusweka kwa workpiece.Kuonjezera manganese ndi silicon kumawonjezera kutenthedwa kwachitsulo.

Tsatanetsatane wa Zamalonda

| Gulu la Zitsulo: | 15CrMo, 12CrMoV, EN: S235JR, S275JR, S355JR, S420NL, S460NL, S500Q, S550Q, S620Q, S690Q ASTM: Grade B, Grade C, Grade D, A36, Grade 36, Grade 40, Grade 42, Grade 50, Grade 55, Grade 60, Grade 65, Grade 70, GradeJIS:SPHC, SS400, SPFC, SPHD, SPHE |

| Zokhazikika: | DIN EN 10083,ASME SA516, ASTM A203M,ASME SA588,ASME SA387,SAE1045 JIS G4051, AISI, BS |

| Makulidwe: | 1.0-300 mm |

| M'lifupi: | 100-4500mm, kapena malinga ndi pempho lapadera la kasitomala |

| Utali: | 1-20meters, kapena malinga ndi pempho lapadera la kasitomala |

| Phukusi: | Tumizani Phukusi Lokhazikika |

| Ntchito: | 1.Machinery, Pressure chombo mafakitale. 2.Kumanga zombo, zomangamanga Engineering. 3.Magalimoto, Milatho, Nyumba. 4.Kupanga makina, Pavement slab, ect. |

| Mill MTC: | Amaperekedwa asanatumizidwe |

| Kuyendera: | The Third Party kuyendera akhoza kulandiridwa, SGS, BV, TUV |

| Mount Port: | Doko lililonse ku China |

| Nthawi Yamalonda: | FOB, CIF, CFR, EXW, etc. |

| Nthawi Yamtengo: | TT kapena LC pakuwona |

| Ntchito Zathu: | Titha kudula ndi kupinda mbale zitsulo malinga ndi requriement kasitomala kapena kujambula, ma CD malinga ndi pempho makasitomala ' |

Chiwonetsero cha Fakitale